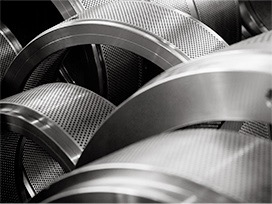

Dies

Quality is no Coincidence

Non-stop precision

Our dies exhibit the quality you expect, especially under high loads. This is a result of our skilled and well established team, with modern production methods and supported by the entire in-house quality process.

It’s the little things that can make a big difference. In the hardening stage, our methods produce a die with maximum concentricity, optimum hardness in terms of resistance to breakage, and a long life.

Our dies are always gun-drilled and run-in at the factory; these results in a highly polished bore, meaning the die can be put into operation immediately with no starting up period

Inspection and Testing

During the final inspection, all dies are checked for dimensional and concentric accuracy. The running in of the die is a matter of course for us.

Only when the die has been run in will it be prepared for delivery; for us, it is important that the die is able to perform at full capacity from the very beginning.