Grain dryers

There is wide range of equipment for grain drying allows arriving at a solution for each project. This is high-quality driers for various grain types of different efficiency and drying percent.

These models are not only the best sellers in Europe, but also comply with strict technical and hygienic standards approved in West Europe.

Gas, electricity and diesel fuel can be used as energy carrier.

Ventilation is performed by means of axial or centrifugal ventilators with dust collector, mini centrifugal collector and rotary valve. Equipment set also includes motor with air silencer and dust collector.

Product unloading can be performed by means of unloading rolls. Air cleaning can be provided before its atmospheric emission.

Control board includes temperature gauges, sensors of filling and discharging, interval and temperature control of product passing.

Drying percent depends on grain type and product humidity head grade. For one cycle grain humidity can be reduced on the average by 4% – 6%, and for corn by 10% – 15%. Efficiency: from 1 to 80 t/h.

Quality

The Continuous flow dryer is manufactured to industrial standards from 2-3 mm galvanised steel plate. Its design ensures effective usage, minimal running and maintenance costs and a long lifetime.

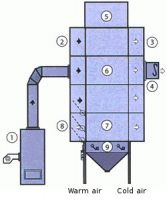

1. Furnace

2. Heat side

3. Suction side

4. Ventilator fan

5. Pre-hopper

6. Drying zone

7. Cooling zone

8. Vent for regulation of drying and cooling zones

9. Base section with outlet funnel

Matching your needs

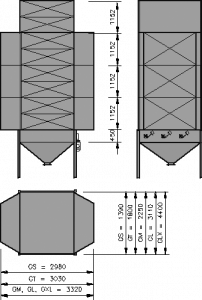

The dryer column is manufactured in 5 standard sizes: GS, GT, GM, GL, GXL.

The number of drying and cooling sections in the column may be varied making it possible to adapt capacity and reduction of water content to individual drying and cooling needs and local conditions.

Discharge regulation ensures that run through times can be adjusted likewise.

Continuous dryers can be supplied with direct or indirect heat sources including natural gas and diesel, with or without dust extraction.

Homogeneous and uniform drying

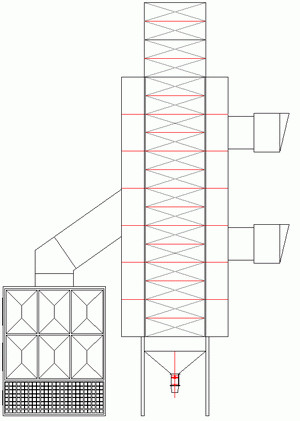

Each dryer section is equipped with a number of V-shaped air channels. These channels are narrowed at one end, designed so that the product only comes into contact with smooth surfaces and are staggered in relation to each other ensuring a uniform distancebetween the channels and an even product distribu tion throughout the dryer column. Air is sucked from the air channels across the grain.

As a result a vacuum is created which minimises heat loss and dust. The uniform passage of the grain through the dryer ensures that every single grain isaffected from all directions and ensures a homoge neous drying.

Discharge regulation

The dried product is discharged via motor driven dis charge rollers. Rate of discharge is controlled from the switchboard using interval regulation.

The discharge trays under the rollers are equiped with springs to prevent foreign bodies from damage ing the rollers. The easily regulated active discharge ensures a homogeneous passage through the dryer and provides complete control of the drying process.

Complete control

The drying process is controlled and monitored from a single control panel with a built-in safety cut-off switch. Level sensors may be placed in the pre-hopper in order to ensure that the top dryer section remains full during operation. The dryer section may also be equipped with temperature sensors.

The control panel may be supplemented with control of associated transport equipment.

Technical data

| Weight incl. Grain (ton) | Total height(meter) | |||||||||

| Sec tions | GS | GT | GM | GL | GXL | GS | GT | GM | GL | GXL |

| 2 | 7 | 10 | - | - | - | 5 | 5.2 | - | - | - |

| 3 | 9 | 12 | 15 | 22 | 31 | 6.1 | 6.3 | 6.5 | 7 | 7.7 |

| 4 | 12 | 16 | 19 | 27 | 39 | 7.3 | 7.5 | 7.7 | 8.2 | 8.8 |

| 5 | 14 | 20 | 23 | 32 | 46 | 8.4 | 8.6 | 8.8 | 9.4 | 10 |

| 6 | 16 | 22 | 26 | 37 | 53 | 9.6 | 9.8 | 10 | 10.5 | 11.1 |

| 7 | 18 | 25 | 30 | 42 | 60 | 10.7 | 10.9 | 11.1 | 11.6 | 12.3 |

| 8 | 21 | 29 | 34 | 47 | 67 | 11.9 | 12.1 | 12.3 | 12.8 | 13.4 |

| 9 | - | - | - | 52 | 74 | - | - | - | 14.0 | 14.6 |

| 10 | - | - | - | 57 | 81 | - | - | - | 15.1 | 15.7 |

| 11 | - | - | - | 62 | 89 | - | - | - | 16.3 | 16.9 |

| 12 | - | - | - | 67 | 96 | - | - | - | 17.4 | 18.0 |

| Capacity (ton/hour) | Heat demand (kW) | |||||||||

| Sec tions | GS | GT | GM | GL | GXL | GS | GT | GM | GL | GXL |

| 2 | 2.9 | 3.8 | - | - | - | 180 | 240 | - | - | - |

| 3 | 4.8 | 6.4 | 8 | 11.2 | 16.0 | 280 | 380 | 480 | 680 | 971 |

| 4 | 5.8 | 7.7 | 9.6 | 13.4 | 19.1 | 350 | 460 | 570 | 800 | 1143 |

| 5 | 7.7 | 10.2 | 12.7 | 18.3 | 26.1 | 460 | 610 | 760 | 1070 | 1529 |

| 6 | 8.7 | 11.5 | 14.4 | 20.2 | 28.9 | 520 | 680 | 870 | 1220 | 1743 |

| 7 | 10.5 | 13.9 | 17.7 | 24.9 | 35.6 | 640 | 850 | 1070 | 1500 | 2143 |

| 8 | 11.4 | 15.1 | 19.1 | 27.0 | 38.6 | 700 | 930 | 1140 | 1600 | 2286 |

| 9 | - | - | - | 31.6 | 45.1 | - | - | - | 1850 | 2643 |

| 10 | - | - | - | 33.8 | 48.3 | - | - | - | 1960 | 2800 |

| 11 | - | - | - | 38.5 | 55.0 | - | - | - | 2350 | 3357 |

| 12 | - | - | - | 40.6 | 58.0 | - | - | - | 2450 | 3500 |

Assumptions:

Capacity is quoted as intake capacity for Barley dried from 20-16% at air temperature 85° C. External air temperature 15° C with 75% humidity. Cooling 5-10 ° C above cooling temperature.

Content per section:

| Type | GS | GT | GM | GL | GXL |

| m3 | 2.28 | 3.04 | 3.8 | 5.3 | 7.6 |

| tons | 1.7 | 2.26 | 2.8 | 4.0 | 5.6 |

| Air content per section: | |||||

| Type | GS | GT | GM | GL | GXL |

| Nm3 | 5100 | 6800 | 8500 | 12000 | 17000 |

All measurements are quoted in mm