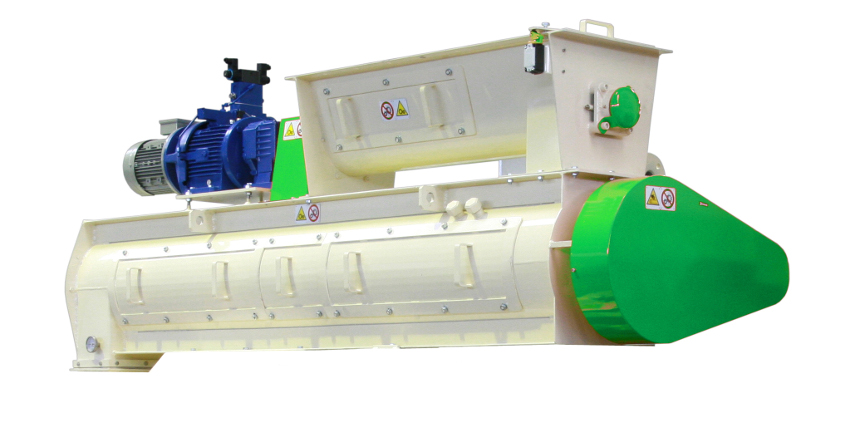

Mixer-conditioner

This machine is capable of conditioning meal prior to pelleting. Steam and liquids can be added and retention times controlled. Body, main shaft, paddles and all surface which has contact with products are produced from stainless steel.

The stainless-steel conditioner mixer has large paddles whose height and angle can be adjusted to provide homogenous mixing and a hygienic process.

Features:

Optimum absorption of steam and liquids, homogeneous mixing

Solid mixer shaft with interchangeable paddles, adjustable in both height and pitch

Transmission via V-belts

Large inspection hatches

PT 100 temperature sensor

1 steam inlet and 2 Liquid inlets 1 ½”

Capacities between 12 – 30 tons / hour

Heated and isolated body as an option

At pelletizing can also use dual conditioning, which provides for some recipes full heat treatment at the maximum being in the zone of influence of 40 seconds at the required performance.

Single Conditioner

| Type | Diam. Mixer | Length Mixer | Motorpower | Volume dm3 |

| MC 160 x 810 | 162 mm. | 816 mm. | 0.75 kW | 16.8 |

| MC 242 x 1010 | 242 mm. | 1010 mm. | 4.00 kW | 46.4 |

| MC 305 x 1600 | 305 mm. | 1605 mm. | 5.50 kW | 117.2 |

| MC 400 x 1830 | 400 mm. | 1834 mm. | 5.50 kW | 230.4 |

| MC 400 x 2150 | 400 mm. | 2154 mm. | 9.00 kW | 270.5 |

| MC 400 x 2310 | 400 mm. | 2314 mm. | 9.00 kW | 290.6 |

| MC 400 x 2360 | 400 mm. | 2364 mm. | 11.00 kW | 330.8 |

| MC 400 x 3110 | 400 mm. | 3114 mm. | 15.00 kW | 391.1 |

| MC 500 x 1830 | 400 mm. | 1834 mm. | 11.00 kW | 345.7 |

| MC 500 x 2150 | 400 mm. | 2154 mm. | 11.00 kW | 406.0 |

| MC 500 x 2310 | 400 mm. | 2314 mm. | 11.00 kW | 436.1 |

| MC 500 x 2360 | 400 mm. | 2364 mm. | 15.00 kW | 496.5 |

| MC 500 x 3110 | 400 mm. | 3114 mm. | 22.00 kW | 586.9 |