Production of full-fat soybean

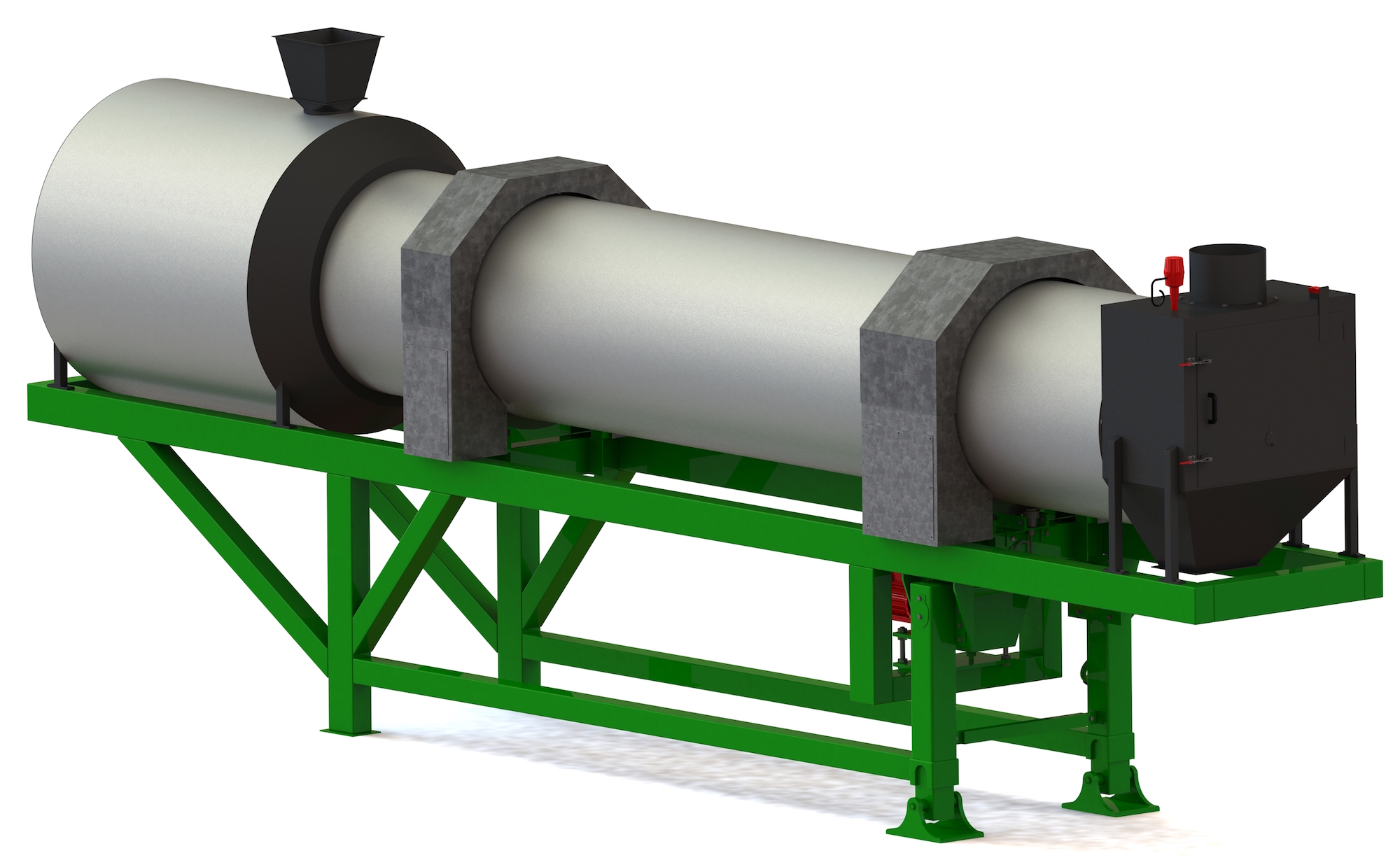

Toaster (Rotary Oven)

Toaster (rotary oven) is designed to dry and toast grain and similar free-flowing products such as wheat, barley, soya beans, pulses and oilseeds, and also for thermal processing of eggshell.

Drying Toaster (rotary oven) is well suited to drying products with a high water content or a consistency which makes them unsuited to drying in a column dryer. Energy efficient drying is achieved when the rotary oven is deployed together with a Counter-flow

cooler:

Oven temperature: 200ºC – 960ºC

Product temperature: 45ºC – 120ºC

Energy consumption: 800 – 950 kcal/Kg water removed

Gelatinisation

Wheat, oats, barley and maize for animal feed

Infra-red radiation penetrates cereal husks creating high internal temperatures and efficiently breaking down complex starches thus increasing digestibility and adding to the nutritional value of the treated product without a long destructive heating process.

Sterilisation

Cereals for consumer products and animal feed

Exposure to temperatures between 100 ºC -120ºC reduces the bacterial and fungal count significantly and effectively sterilises cereals without significantly breaking down amino acids and vitamins.

Conditioning /flaking

Cereals and pulses for consumer products such as Muesli and health food products, and animal feeds including pet food mixtures.

Following gelatinisation or pre-cooking, cereals, soya beans and pulses are soft and malleable. Processed cereals can be flaked without significant dust production and without loss of natural colour and appearance.

Toasting

Soya beans and pulses for animal feeds

Raw materials such as soya beans and pulses cannot be used as feed without prior processing due to the presence of biologically active inhibitors, such as trypsin, urea and other known allergy inducing agents. Short term exposure to temperatures in excess of 138 ºC significantly reduces bacteria and destroys inhibitors.

| Typical analysis for processed wheat: | Bacteriology: | ||

| Protein | 12.5% | Total count | < 10.000 / g |

| Carbohydrates | 72.5% | Yeast | < 1.000 / g |

| Ash | 1.5% | Mould | < 1.000 / g |

| Moisture | 8.5% | Hemolytic bacteria | < 1.000 / g |

| Fibre | 3.0% | B. cereus | < 100 / g |

| Fat | 2.0% | Salmonella | no trace in 50 g |

| Total | 100% | ||

| Тypical analysis for toasted soya beans: | Bacteriology: | ||

| Protein | 38.0% | Total count | < 10.000 / g |

| Carbohydrates | 25.0% | Yeast | < 1.000 / g |

| Ash | 5.0% | Mould | < 1.000 / g |

| Moisture | 7.5% | Hemolytic bacteria | < 1.000 / g |

| Fibre | 5.5% | B. cereus | < 100 / g |

| Fat | 19.0% | Salmonella | no trace in 50 g |

| Total | 100% | Urea | 0.02 -0.2 mg N / g /min |

| Type | A | B | C | D | E | F | G |

| AT 800 | 1350 | 6600 | 6980 | Ø900 | Ø1270 | 2430 | 800 |

| AT 1500 | 2470 | 7800 | 8250 | Ø1200 | Ø1620 | 2690 | 800 |

| AT 2500 | 2300 | 8900 | 9600 | Ø1360 | Ø1860 | 2910 | 800 |

| AT 2500 S | 3000 | 10900 | 11150 | Ø1608 | Ø2130 | 3210 | 800 |

| Type | AT 800 | AT 1500 | AT 2500 | AT 2500S | |||

| Power burner unit (kW) | 800 | 1500 | 2500 | 2700 | |||

| Water evaporation capacity (kg/h) | 800 | 1500 | 2500 | 2700 | |||

| Air outlet at 110 C (m3/h) | 7000 | 11000 | 16000 | 22000 at 85-95 ºС |

|||

Technical data